+8615360903247

Junda is a trusted manufacturer and supplier of rear rack eBike batteries in China. We specialize in providing customized rear rack battery solutions tailored to the needs of e-bike brands, OEMs, and distributors. Whether your design requires specific voltage, capacity, or mounting compatibility, our team ensures reliable performance, certified safety, and seamless integration—delivering durable power solutions built for long-lasting urban and commuter use.

As a leading supplier of rear rack eBike batteries in China, Junda brings over a decade of experience and strong in-house manufacturing capabilities. We support both custom development and small-to-medium batch production, ensuring flexibility for your business model. Our rear rack battery packs are available in a range of voltages, capacities, and connector types, all engineered for reliable performance and compatibility with popular e-bike frames.

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 24V | 10.4Ah | DMEGC 2600 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12Ah | DMEGC 3000 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12.8Ah | DMEGC 3200 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 14Ah | Samsung 35E | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 7.8Ah | DMEGC 2600 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9Ah | DMEGC 3000 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9.6Ah | DMEGC 3200 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 10.5Ah | Samsung 35E | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 24V | 10.4Ah | DMEGC 2600 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12Ah | DMEGC 3000 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12.8Ah | DMEGC 3200 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 14Ah | Samsung 35E | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 7.8Ah | DMEGC 2600 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9Ah | DMEGC 3000 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9.6Ah | DMEGC 3200 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 10.5Ah | Samsung 35E | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 24V | 10.4Ah | DMEGC 2600 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12Ah | DMEGC 3000 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12.8Ah | DMEGC 3200 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 14Ah | Samsung 35E | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 7.8Ah | DMEGC 2600 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9Ah | DMEGC 3000 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9.6Ah | DMEGC 3200 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 10.5Ah | Samsung 35E | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 10.4Ah | DMEGC 2600 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12Ah | DMEGC 3000 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12.8Ah | DMEGC 3200 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 14Ah | Samsung 35E | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 7.8Ah | DMEGC 2600 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9Ah | DMEGC 3000 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9.6Ah | DMEGC 3200 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.5Ah | Samsung 35E | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 10.4Ah | DMEGC 2600 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12Ah | DMEGC 3000 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12.8Ah | DMEGC 3200 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 14Ah | Samsung 35E | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 7.8Ah | DMEGC 2600 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9Ah | DMEGC 3000 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9.6Ah | DMEGC 3200 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.5Ah | Samsung 35E | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 10.4Ah | DMEGC 2600 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12Ah | DMEGC 3000 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12.8Ah | DMEGC 3200 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 14Ah | Samsung 35E | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 7.8Ah | DMEGC 2600 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9Ah | DMEGC 3000 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9.6Ah | DMEGC 3200 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.5Ah | Samsung 35E | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 13Ah | DMEGC 2600 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 15Ah | DMEGC 3000 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 16Ah | DMEGC 3200 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 17.5Ah | Samsung 35E | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.4Ah | DMEGC 2600 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12Ah | DMEGC 3000 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12.8Ah | DMEGC 3200 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 14Ah | Samsung 35E | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 13Ah | DMEGC 2600 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 15Ah | DMEGC 3000 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 16Ah | DMEGC 3200 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 17.5Ah | Samsung 35E | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.4Ah | DMEGC 2600 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12Ah | DMEGC 3000 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12.8Ah | DMEGC 3200 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 14Ah | Samsung 35E | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 13Ah | DMEGC 2600 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 15Ah | DMEGC 3000 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 16Ah | DMEGC 3200 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 17.5Ah | Samsung 35E | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.4Ah | DMEGC 2600 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12Ah | DMEGC 3000 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12.8Ah | DMEGC 3200 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 14Ah | Samsung 35E | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 13Ah | DMEGC 2600 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 15.6Ah | DMEGC 2600 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 18Ah | DMEGC 3000 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 19.2Ah | DMEGC 3200 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 21Ah | Samsung 35E | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.4Ah | DMEGC 2600 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12Ah | DMEGC 3000 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12.8Ah | DMEGC 3200 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 14Ah | Samsung 35E | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 13Ah | DMEGC 2600 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 15.6Ah | DMEGC 2600 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 18Ah | DMEGC 3000 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 19.2Ah | DMEGC 3200 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 21Ah | Samsung 35E | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.4Ah | DMEGC 2600 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12Ah | DMEGC 3000 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12.8Ah | DMEGC 3200 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 14Ah | Samsung 35E | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 13Ah | DMEGC 2600 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 15.6Ah | DMEGC 2600 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 18Ah | DMEGC 3000 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 19.2Ah | DMEGC 3200 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 21Ah | Samsung 35E | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.4Ah | DMEGC 2600 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12Ah | DMEGC 3000 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 12.8Ah | DMEGC 3200 | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 14Ah | Samsung 35E | 13S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 8Ah | DMEGC 2600 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9.6Ah | DMEGC 3000 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 10.5Ah | Samsung 35E | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 10.4Ah | DMEGC 2600 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12Ah | DMEGC 3000 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12.8Ah | DMEGC 3200 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 14Ah | Samsung 35E | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 7.8Ah | DMEGC 2600 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9Ah | DMEGC 3000 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9.6Ah | DMEGC 3200 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.5Ah | Samsung 35E | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 10.4Ah | DMEGC 2600 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12Ah | DMEGC 3000 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12.8Ah | DMEGC 3200 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 14Ah | Samsung 35E | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 7.8Ah | DMEGC 2600 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9Ah | DMEGC 3000 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9.6Ah | DMEGC 3200 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.5Ah | Samsung 35E | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 10.4Ah | DMEGC 2600 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12Ah | DMEGC 3000 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12.8Ah | DMEGC 3200 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 14Ah | Samsung 35E | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 7.8Ah | DMEGC 2600 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9Ah | DMEGC 3000 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9.6Ah | DMEGC 3200 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.5Ah | Samsung 35E | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 23.4Ah | DMEGC 2600 | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 27Ah | DMEGC 3000 | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 28.8Ah | DMEGC 3200 | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 31.5Ah | Samsung 35E | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 18.2Ah | DMEGC 2600 | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 21Ah | DMEGC 3000 | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 22.4Ah | DMEGC 3200 | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 24.5Ah | Samsung 35E | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 15.6Ah | DMEGC 2600 | 14S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 18Ah | DMEGC 3000 | 14S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 19.2Ah | DMEGC 3200 | 14S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 21Ah | Samsung 35E | 14S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 24V | 10.4Ah | DMEGC 2600 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12Ah | DMEGC 3000 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 12.8Ah | DMEGC 3200 | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 24V | 14Ah | Samsung 35E | 7S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 7.8Ah | DMEGC 2600 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9Ah | DMEGC 3000 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 9.6Ah | DMEGC 3200 | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 10.5Ah | Samsung 35E | 10S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 10.4Ah | DMEGC 2600 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12Ah | DMEGC 3000 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 12.8Ah | DMEGC 3200 | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 14Ah | Samsung 35E | 10S4P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 7.8Ah | DMEGC 2600 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9Ah | DMEGC 3000 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 9.6Ah | DMEGC 3200 | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 10.5Ah | Samsung 35E | 13S3P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 13Ah | DMEGC 2600 | 10S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 15.6Ah | DMEGC 2600 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 18Ah | DMEGC 3000 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 19.2Ah | DMEGC 3200 | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 21Ah | Samsung 35E | 10S6P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 13Ah | DMEGC 2600 | 13S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 15Ah | DMEGC 3000 | 13S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 16Ah | DMEGC 3200 | 13S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 17.5Ah | Samsung 35E | 13S5P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 23.4Ah | DMEGC 2600 | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 27Ah | DMEGC 3000 | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 28.8Ah | DMEGC 3200 | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 31.5Ah | Samsung 35E | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 18.2Ah | DMEGC 2600 | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 21Ah | DMEGC 3000 | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 22.4Ah | DMEGC 3200 | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 24.5Ah | Samsung 35E | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| Voltage | Capacity | Cell | Config | Charge Current (A) | Operating Temp (°C) | Connector | Cycle Life | Warranty | Certs |

|---|---|---|---|---|---|---|---|---|---|

| 36V | 18.2Ah | DMEGC 2600 | 10S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 20.8Ah | DMEGC 2600 | 10S8P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 23.4Ah | DMEGC 2600 | 10S9P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 26Ah | DMEGC 2600 | 10S10P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 30Ah | DMEGC 3000 | 10S10P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 32Ah | DMEGC 3200 | 10S10P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 36V | 35Ah | Samsung 35E | 10S10P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 17.5Ah | DMEGC 2600 | 13S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 20Ah | DMEGC 2600 | 13S8P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 24Ah | DMEGC 3000 | 13S8P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 25.6Ah | DMEGC 3200 | 13S8P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 48V | 28Ah | Samsung 35E | 13S8P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 18.2Ah | DMEGC 2600 | 14S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 21Ah | DMEGC 3000 | 14S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 22.4Ah | DMEGC 3200 | 14S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

| 52V | 24.5Ah | Samsung 35E | 14S7P | 5A | -20~60 / 0~45 | XT60 | 800–1000 cycles | 12 months | UN38.3 / CE |

At Junda, we offer a full range of customization services for rear rack eBike batteries—turning your unique concepts into fully functional power solutions. Backed by robust engineering, in-house assembly, and deep expertise in lithium battery integration, we help you design battery packs that are not only powerful and safe, but also optimized for bike frame compatibility, weight distribution, and user convenience.

Partner with Junda to build rear rack battery packs that match your product vision, technical specs, and commercial goals.

Junda is more than just a rear rack battery supplier—we’re your strategic partner in delivering end-to-end power solutions for electric bikes. Our commitment goes far beyond product delivery. We provide the technical support, customization expertise, and flexible service you need to succeed in a competitive e-bike market.

Can’t find a battery that fits your frame or meets your range requirements? Our team can design it from scratch—including the housing, connector, and internal configuration—based on your specs.

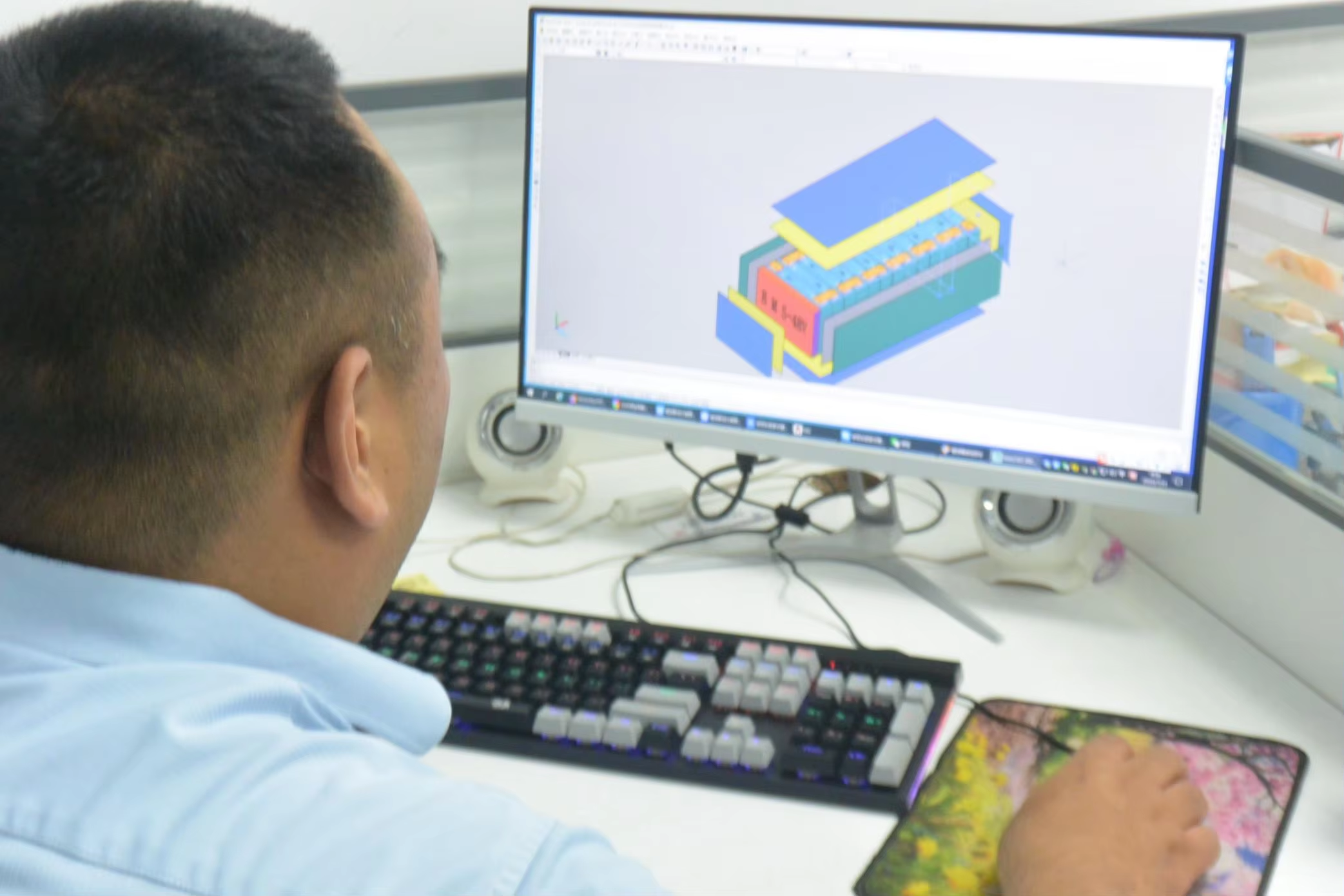

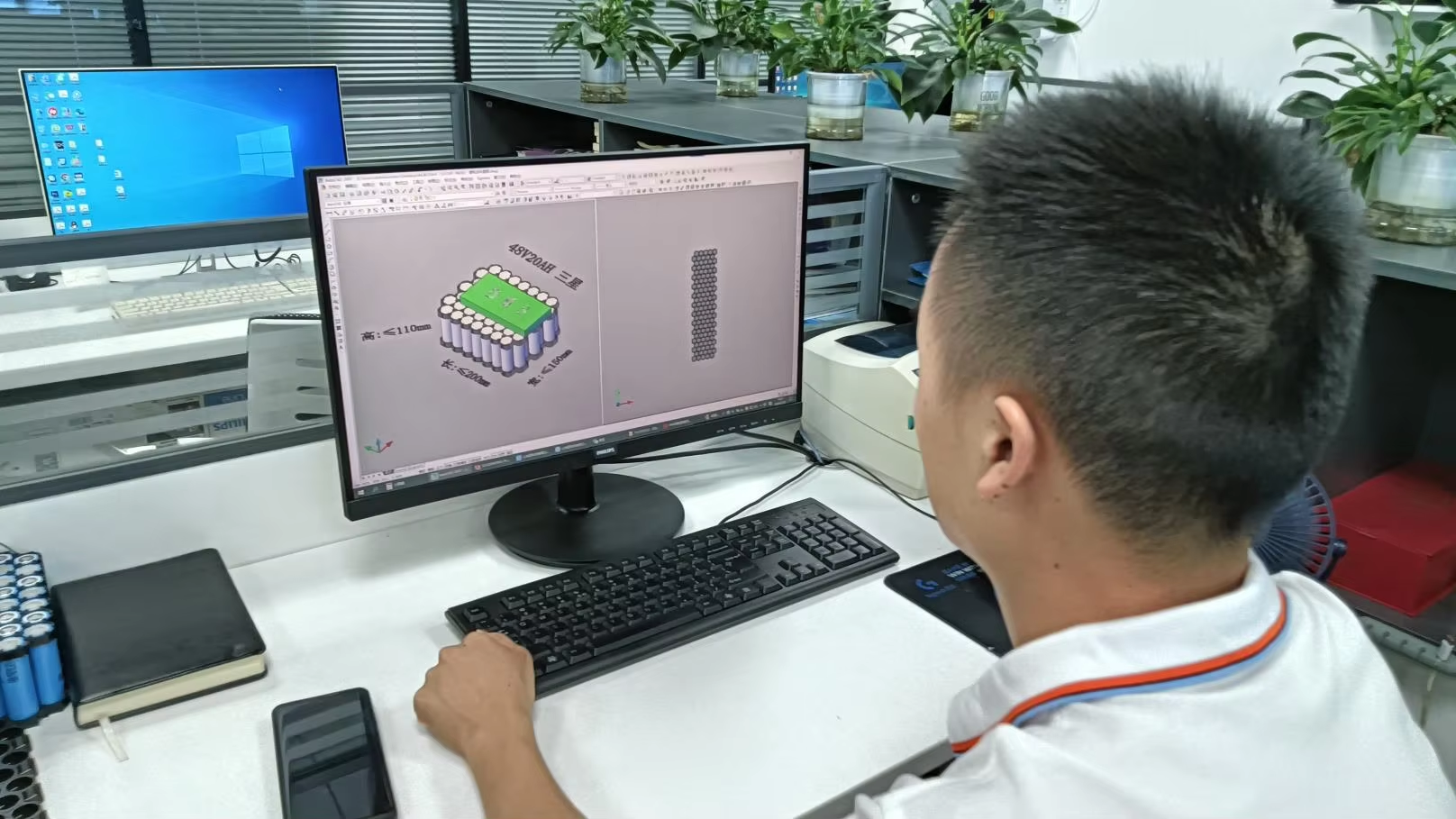

Not sure what voltage, capacity, or output current you need? Just tell us your motor spec and frame dimensions—we’ll propose the optimal battery configuration, complete with 3D models or datasheets.

Worried about large MOQs? We support low-volume sample runs so you can validate fit, performance, and customer response before scaling up.

Our technical team is ready to assist with mounting guidance, wiring diagrams, and installation tips—whether you’re building in-house or working with an OEM assembly line.

At Junda, we understand that every electric bike project is different—especially when it comes to rear rack battery design, fitment, and performance expectations. That’s why we offer flexible, customized battery solutions built to match your technical specs, branding goals, and delivery timeline. Whether you’re launching a new model or upgrading an existing line, we help you power up with confidence.

As a rear rack battery manufacturer with bulk production capabilities, we offer factory-direct pricing, allowing you to maintain margin while delivering certified, reliable battery packs to your customers. We support stable supply, private labeling, and regional warehousing options to help you scale quickly.

Looking to differentiate your eBike product line? We work with brands to co-develop rear rack batteries that match your performance goals and visual identity—from voltage and connector specs to logo, housing color, and packaging design. Let us help turn your vision into a custom battery that builds brand value.

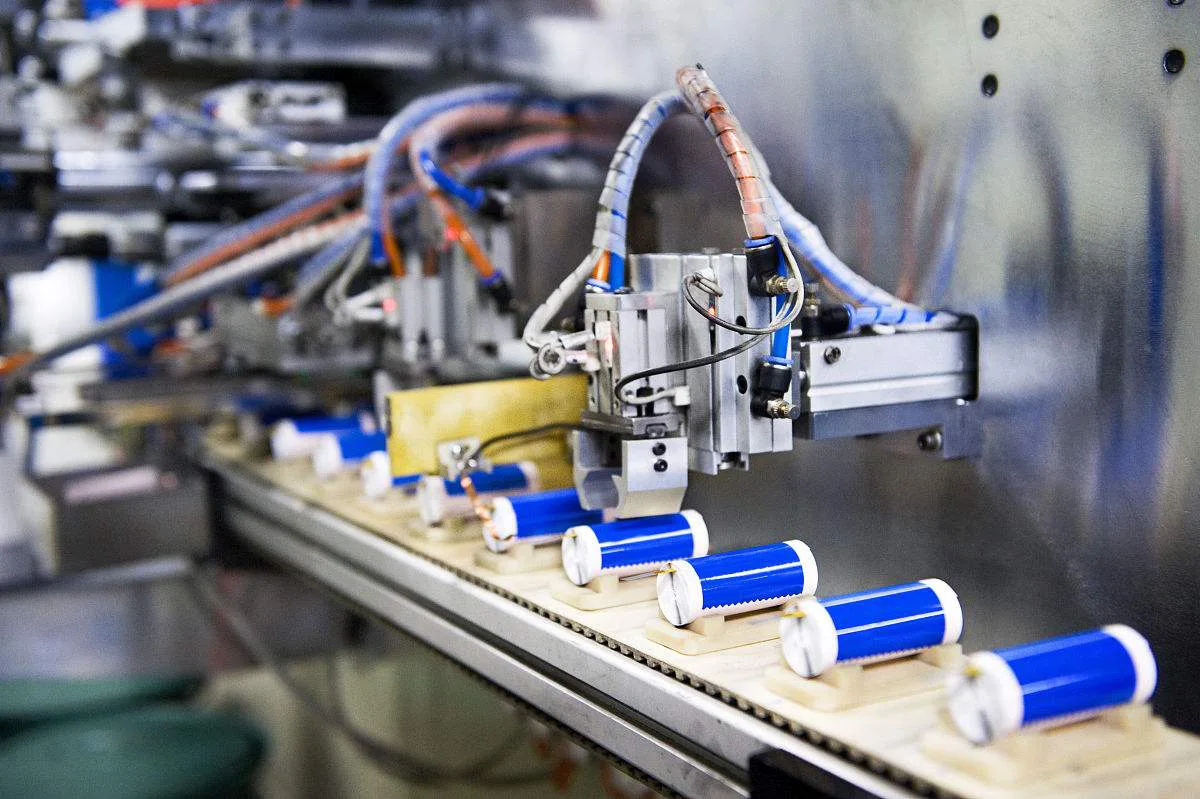

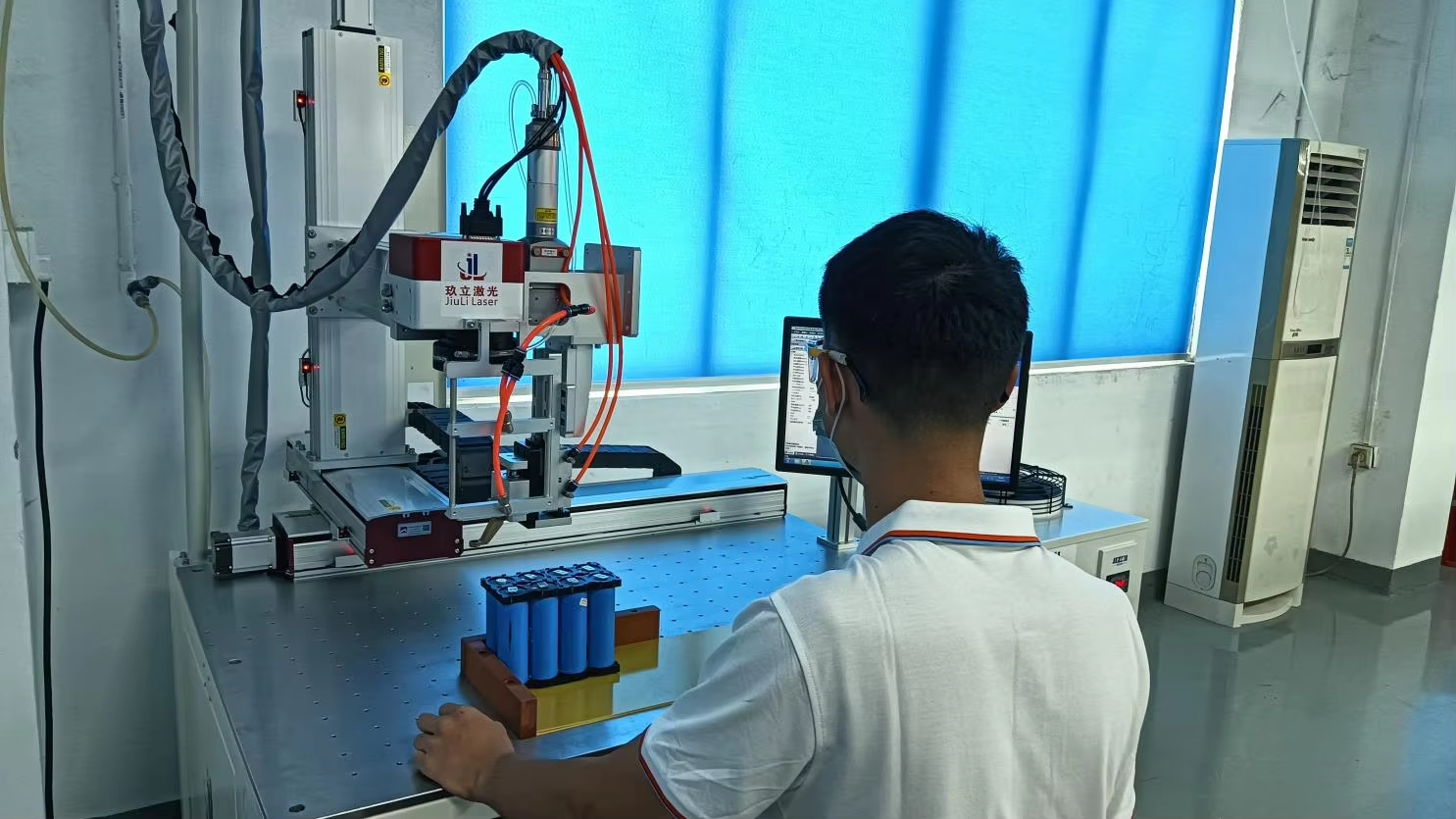

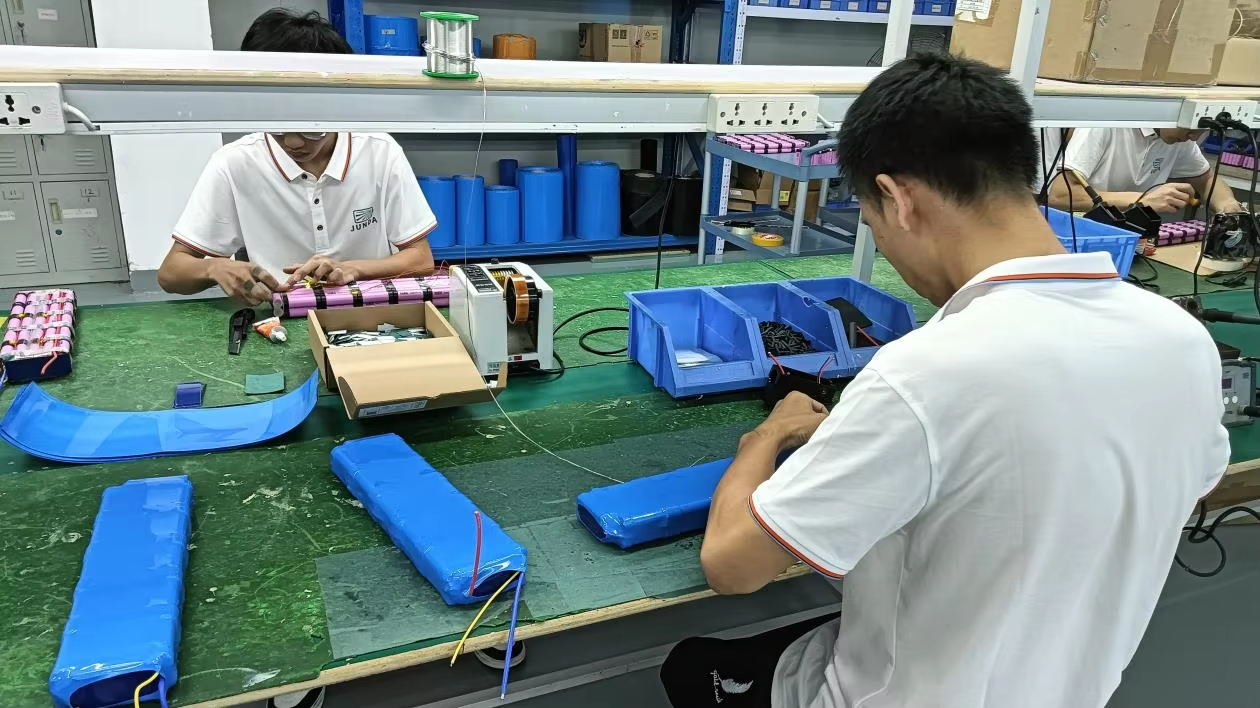

With in-house cell sorting, welding, testing, and assembly, our facility ensures consistent quality and fast production. We help you meet delivery deadlines and compliance requirements, offering tailored designs, technical drawings, and pre-shipment QC reports to simplify your integration process.

Whether you're prototyping a new foldable cargo eBike or testing regional market response, we support low-MOQ production and rapid sampling of rear rack battery packs. From CAD review to final delivery, we shorten your development cycle without compromising quality or safety.

Got more questions? We’re here to help you with every detail.

Rear rack batteries are compatible with most commuter, city, and step-through e-bike designs. Customized formats can match your frame dimensions or motor system.

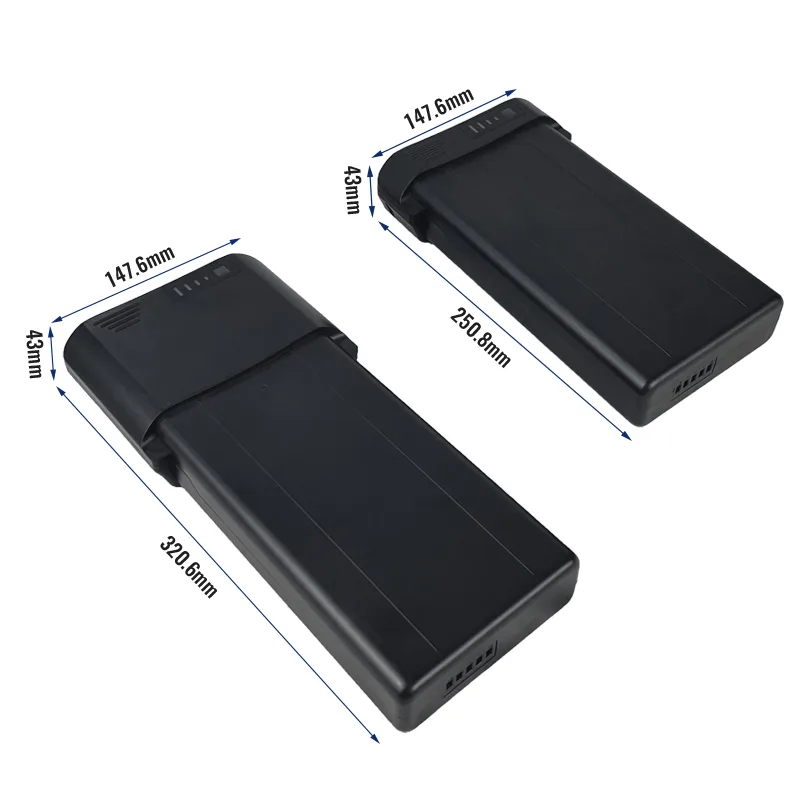

Yes. You can specify voltage (36V / 48V / 52V), capacity (10Ah–20Ah+), connector type (e.g. XT60, Anderson), casing design, and private-label branding.

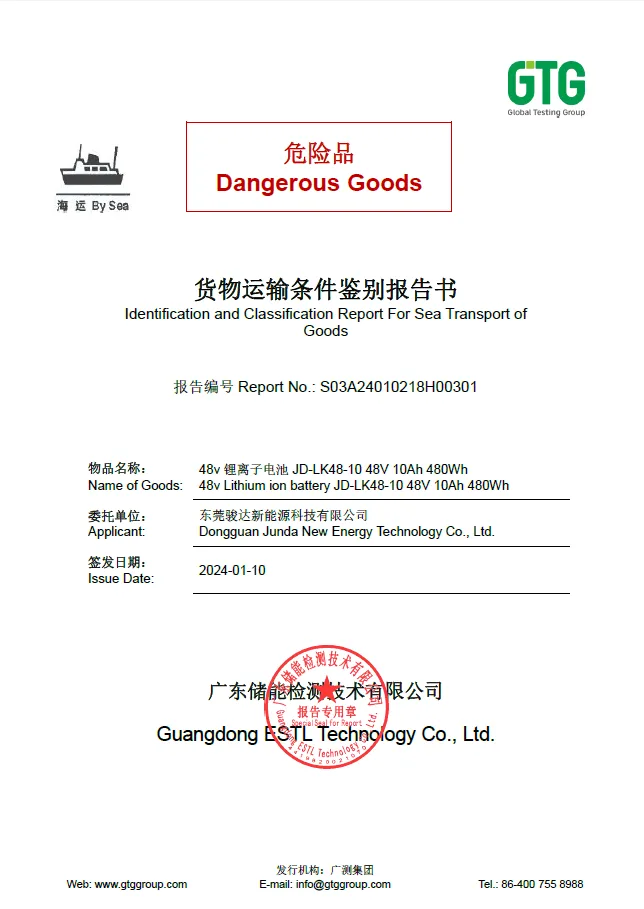

We offer UN38.3, MSDS, IEC 62133, and CE certifications to help you meet market regulations and ensure battery safety.

Standard samples are delivered in 3–7 days. Bulk orders benefit from strong production capacity and overseas warehouse.

You’ll receive technical support, wiring guidance, and warranty options. Our team replies quickly to any issue, and we support replacements or repairs for eligible cases.

MOQ for standard rear rack batteries is 50–100 pcs. For custom housing or BMS designs, MOQ starts from 500 pcs.

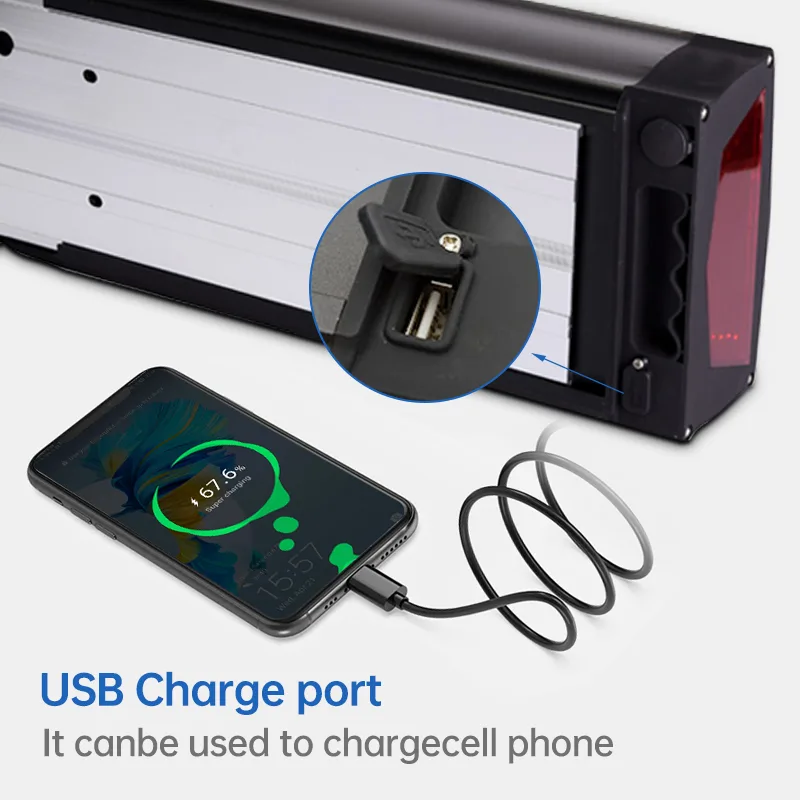

Yes. We can integrate Bluetooth-enabled BMS for remote monitoring, data logging, and diagnostics via mobile apps.

Each battery pack is built with grade-A cells, undergoes 100% QC testing, and passes high-standard electrical, vibration, and aging tests before shipping.

Absolutely. Every shipment includes wiring diagrams, installation guides, and spec sheets. We also offer video support or engineer calls if needed.

Standard warranty is 12 months, with extended coverage available upon request for long-term cooperation partners.

Advanced production lines for certified, high-performance lithium battery packs

Rear rack batteries are a popular choice for city, commuter, and step-through e-bikes—offering easy installation, modular design, and broad compatibility across global e-bike models.

Whether you’re importing for your brand, assembling for OEM production, or distributing to regional partners, this complete buyer’s guide will give you the key information needed to source, customize, and scale your rear rack battery orders with confidence.

Unlock practical insights into specs, certifications, packaging, MOQ, and more—all tailored for B2B success.

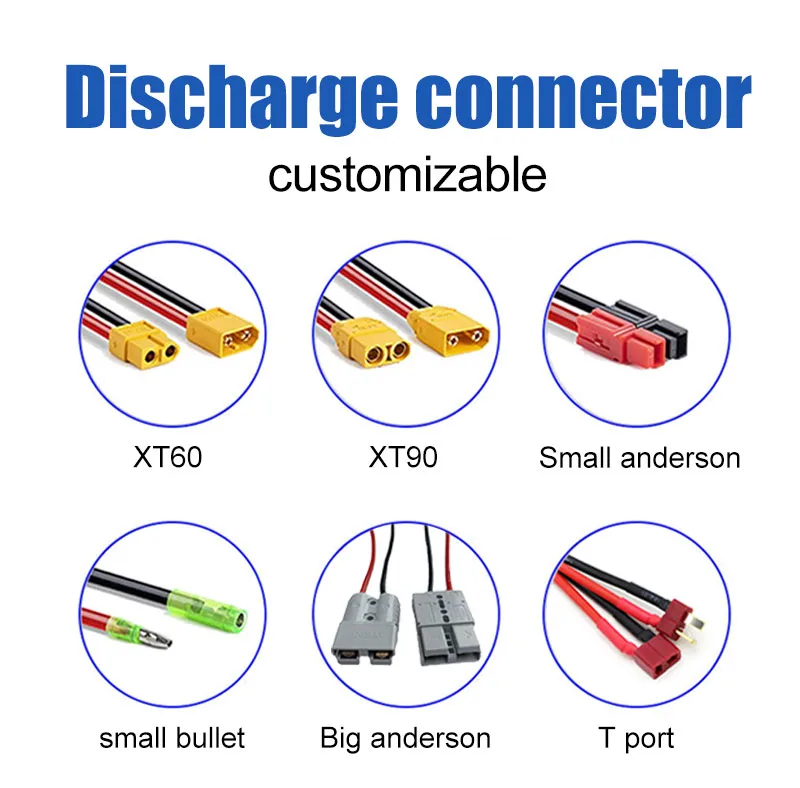

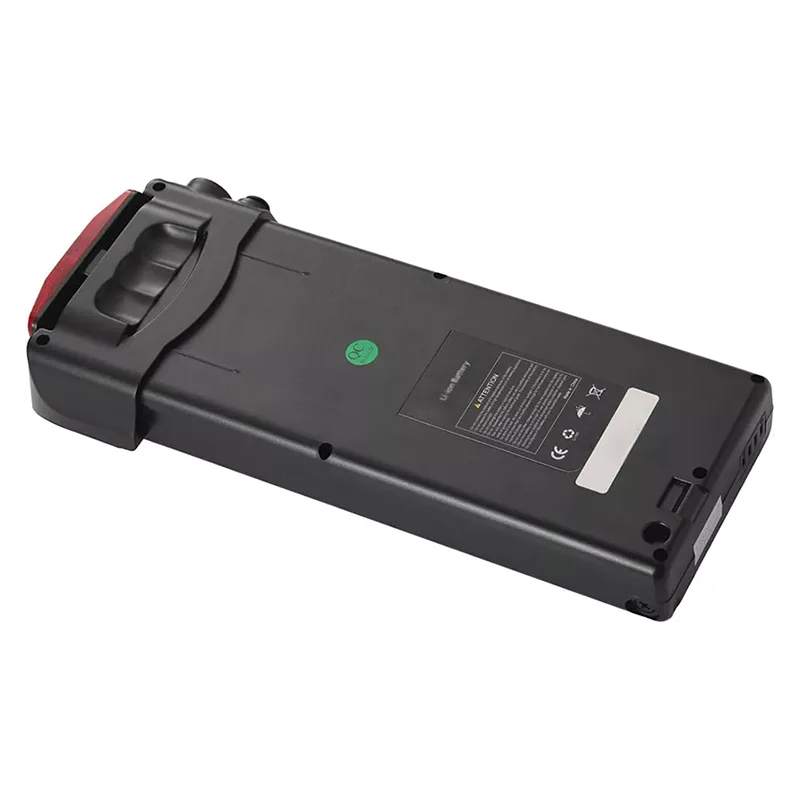

Rear rack battery packs are externally mounted lithium-ion battery systems designed to sit securely on the rear carrier of electric bicycles. This format is especially popular in city bikes, commuter models, and step-through frames, where easy access and weight balance are critical.

These batteries are built with durable outer shells, internal BMS (Battery Management Systems), and high-quality cells to ensure consistent power output and long service life. Their placement not only allows for convenient charging and maintenance, but also helps free up space within the bike frame for other components or design features.

Thanks to their modular structure and standardized mounting, rear rack batteries have become a preferred solution for e-bike brands, OEM assemblers, and fleet operators looking for dependable, user-friendly energy systems.

Rear rack batteries supply DC power to your e-bike’s motor and controller system, enabling pedal-assist or full electric drive. Inside each pack, a series of lithium-ion cells (typically 18650 or 21700) are connected in specific series/parallel configurations to achieve the desired voltage and capacity.

To ensure safety and performance, each battery includes a BMS (Battery Management System) that regulates charge and discharge cycles, balances individual cells, and protects against overcurrent, short circuits, and thermal issues.

Mounted at the rear of the bike, these battery packs are wired directly to the controller, usually through waterproof connectors. Their external placement allows for easy maintenance, while their robust shell protects internal components from vibration and the elements—making them ideal for daily use in urban environments.

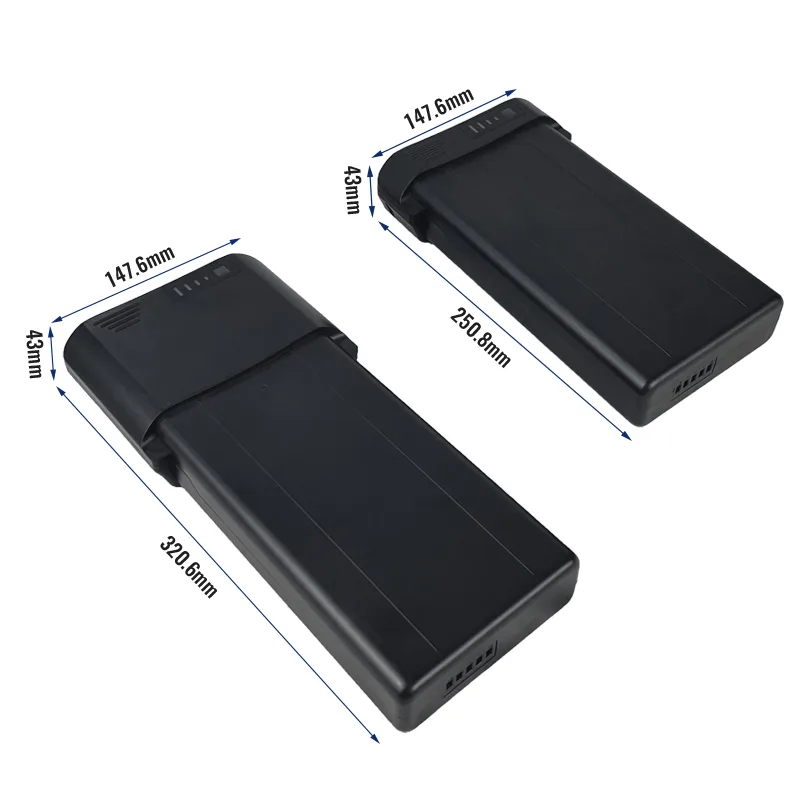

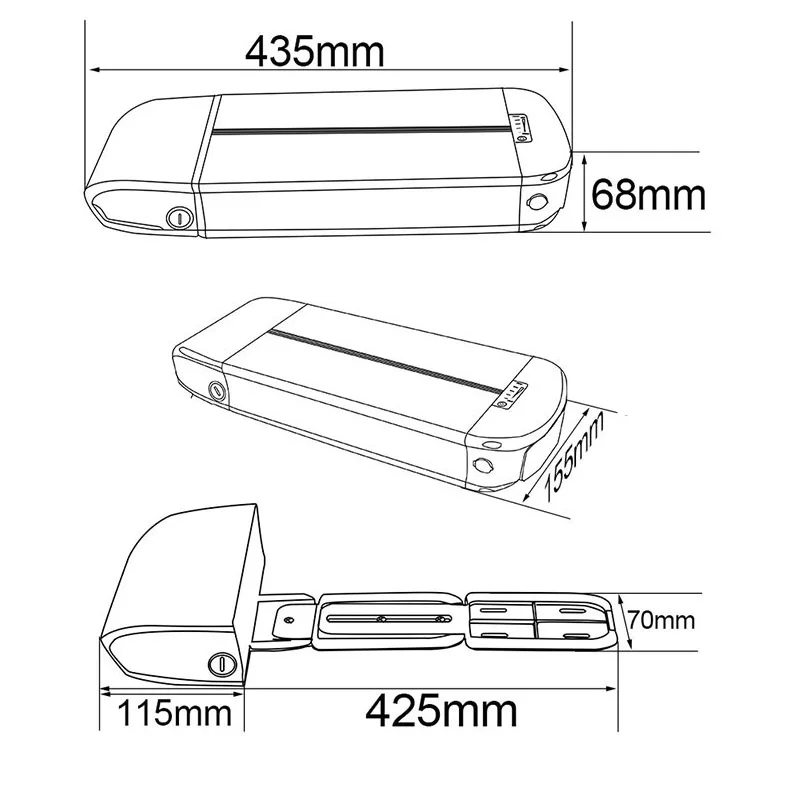

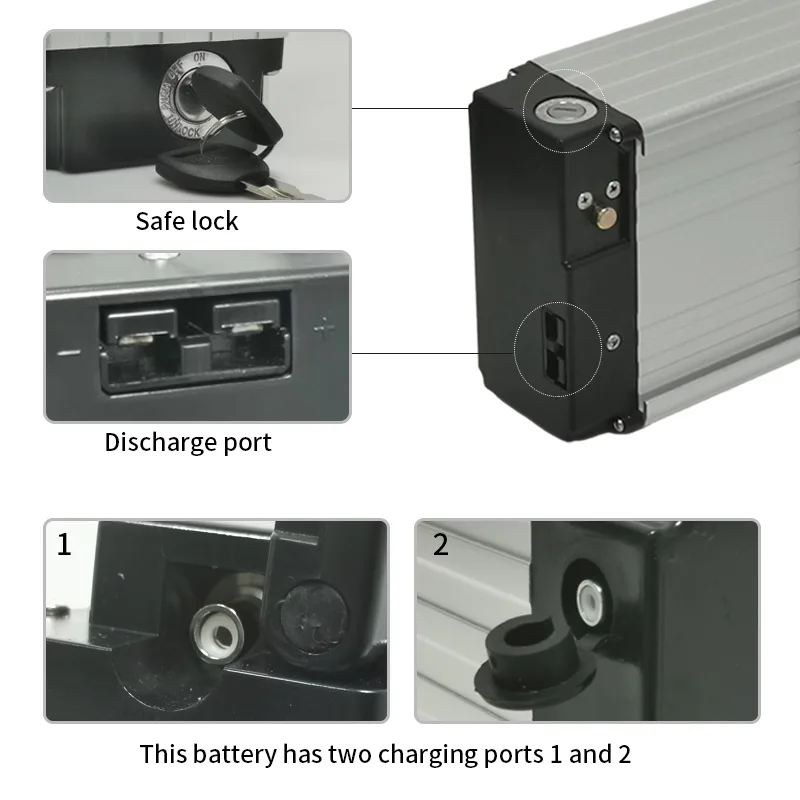

Our rear rack battery packs are engineered for stability, long range, and frame-mounted convenience. Below are the typical specifications:

| Specification | Details |

|---|---|

| Case type | Rear Rack Case (standard or custom aluminum/ABS housing) |

| Cell type | 18650 / 21700 lithium-ion (Samsung, LG, etc.) |

| Voltage options | 36V / 48V / 52V |

| Capacity range | 10Ah – 20Ah |

| Nominal energy | 360Wh – 960Wh |

| Continuous current | 15A – 25A (customizable BMS) |

| BMS features | Overcharge, over-discharge, short circuit, temp control, optional BLE |

| Operating temperature | -20°C ~ 55°C |

| Cycle life | ≥600 cycles (80% DOD) |

| Certifications | UN38.3, MSDS, CE, IEC 62133, RoHS (optional) |

| Connector options | XT60, DC 2-pin, Anderson, or customized |

| LED indicator | Yes (battery level and error alert) |

| Case color/branding | Black / Silver (custom logo, label & color available) |

Rear rack battery packs offer a variety of advantages for electric bicycle manufacturers, assemblers, and distributors seeking compact, versatile, and user-friendly power solutions.

Choosing the right rear rack battery pack is essential for ensuring stable performance, customer satisfaction, and regulatory compliance. This guide helps OEMs, brands, assemblers, and fleet buyers make informed decisions when sourcing rear-mounted battery systems.

Confirm Rear Rack Compatibility:

Ensure your e-bike frame includes or supports a standard rear rack with proper mounting points and load-bearing capacity.

Choose Voltage & Capacity:

Select from 36V, 48V, or 52V depending on your motor controller. Capacity typically ranges from 10Ah to 20Ah to balance range and weight.

Specify Battery Cells:

Go for grade-A cells from Samsung, LG, or equivalent. High-quality cells improve cycle life, reduce after-sales issues, and boost customer confidence.

Define BMS Requirements:

Standard BMS includes protections like overcharge, over-discharge, and short circuit. Bluetooth monitoring or dual-battery switching can be added for advanced models.

Match Connectors & Wiring:

Double-check that the battery’s output connector (e.g., XT60, DC 2-pin, Anderson) matches your controller. Ensure waterproofing and vibration resistance for fleet use.

Check Certifications:

For export to the EU/US, ensure the battery pack includes UN38.3, IEC 62133, MSDS, and RoHS documentation for customs clearance and safety compliance.

Customize Branding & Appearance:

Add your logo, label, or custom color to the rear rack casing to reinforce brand identity—ideal for OEM/private label clients.

Review MOQ & Lead Time:

MOQ typically starts at 100 pcs for standard packs and 500 pcs for custom designs. Confirm production and shipping timelines match your project schedule.

Clarify Warranty Terms:

Choose a supplier with clear warranty policies (e.g., 12–24 months) and quick-response after-sales service for global customers.

Test with Real Frames:

Always request a sample to test battery fit, discharge behavior, and overall system compatibility before moving to mass production.

By following these steps, you can confidently select a rear rack battery that supports your product vision, satisfies end-users, and ensures smooth integration with your supply chain.

At Junda, quality is at the heart of everything we do. Every rear rack battery pack we manufacture undergoes a strict multi-step quality control process to ensure it meets global performance, safety, and compliance standards. Whether you’re serving urban commuters, delivery fleets, or private label brands, we make sure every battery is reliable and ready for the real world.

We implement the following QC benchmarks across every production run:

| Test Items | Test Conditions | Qualification Standard |

|---|---|---|

| Capacity Test | Full charge/discharge using rated current | ≥ Labeled capacity |

| Voltage Accuracy | Measured under no-load and under typical motor load | Within ±1% of rated voltage |

| Cycle Life | 500+ charge cycles at 80% DOD | ≥ 80% capacity retention after 500 cycles |

| BMS Protection | Trigger overcharge, over-discharge, and short-circuit events | All protection circuits respond as designed |

| Temperature Tolerance | Test performance at -20°C to 55°C | No leakage, bulging, or degradation |

| Vibration Test | Simulated riding conditions on bumpy roads | No loose wiring, cracked casings, or failures |

| Compliance Check | Review of required documents (UN38.3, MSDS, CE, RoHS) | Certificates are up-to-date and compliant |

Every rear rack battery must pass all tests before shipping. That’s our standard—and our commitment—to our global B2B partners.If your project involves unique specs, operating conditions, or certification requirements, we can tailor our quality control processes to match your expectations.

Selecting the right Hailong battery pack is easy when you have clear information and expert support.

At Junda, we provide a full range of certified eBike battery packs to meet the needs of global businesses. Our team works closely with each client to ensure the battery solution fits the product, performance goals, and regional compliance standards. With fast lead times, consistent quality, and responsive service, we help you power your eBike business—safely and reliably.

Choose Junda as your trusted supplier for every shipment.

Click to Chat

I'm Online.

Any questions related to our Ebike battery?

WhatsApp Us

🟢 Online | Privacy policy

WhatsApp us

Tell us what you need—we’ll respond with a solution, price, and lead time.