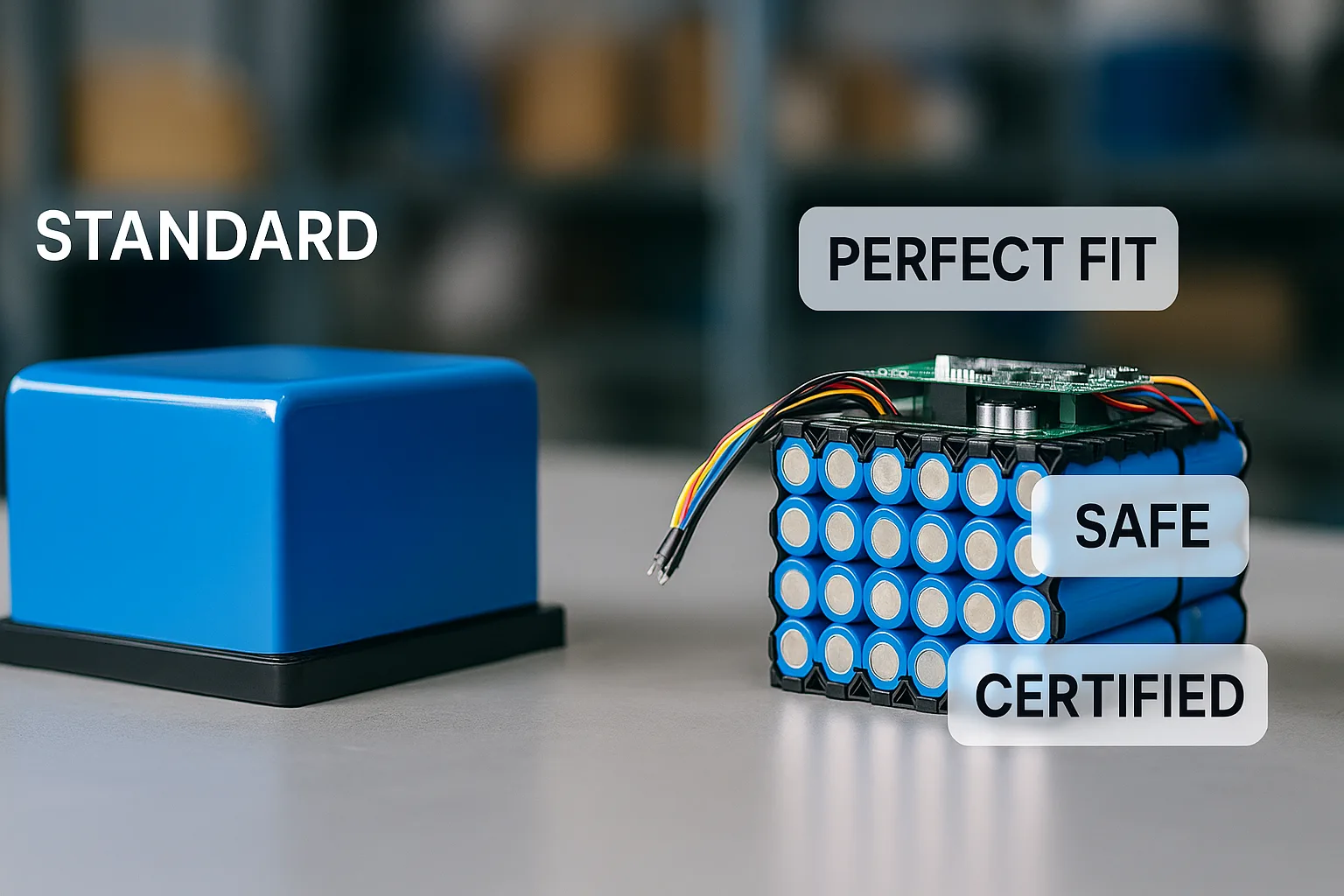

Standard batteries often fail to meet specific device needs. They can cause compatibility issues and even safety risks. Custom battery packs solve these problems perfectly.

Custom battery packs are tailored energy solutions built exactly to your device's voltage, size, and connector specifications, ensuring perfect compatibility, reliability, and performance.

Let me share my experience to show you why choosing custom battery packs can transform your products and improve your business.

What Exactly is a Custom Battery Pack?

When I first started working with e-bikes, I often struggled with mismatched batteries that caused endless problems. Sound familiar?

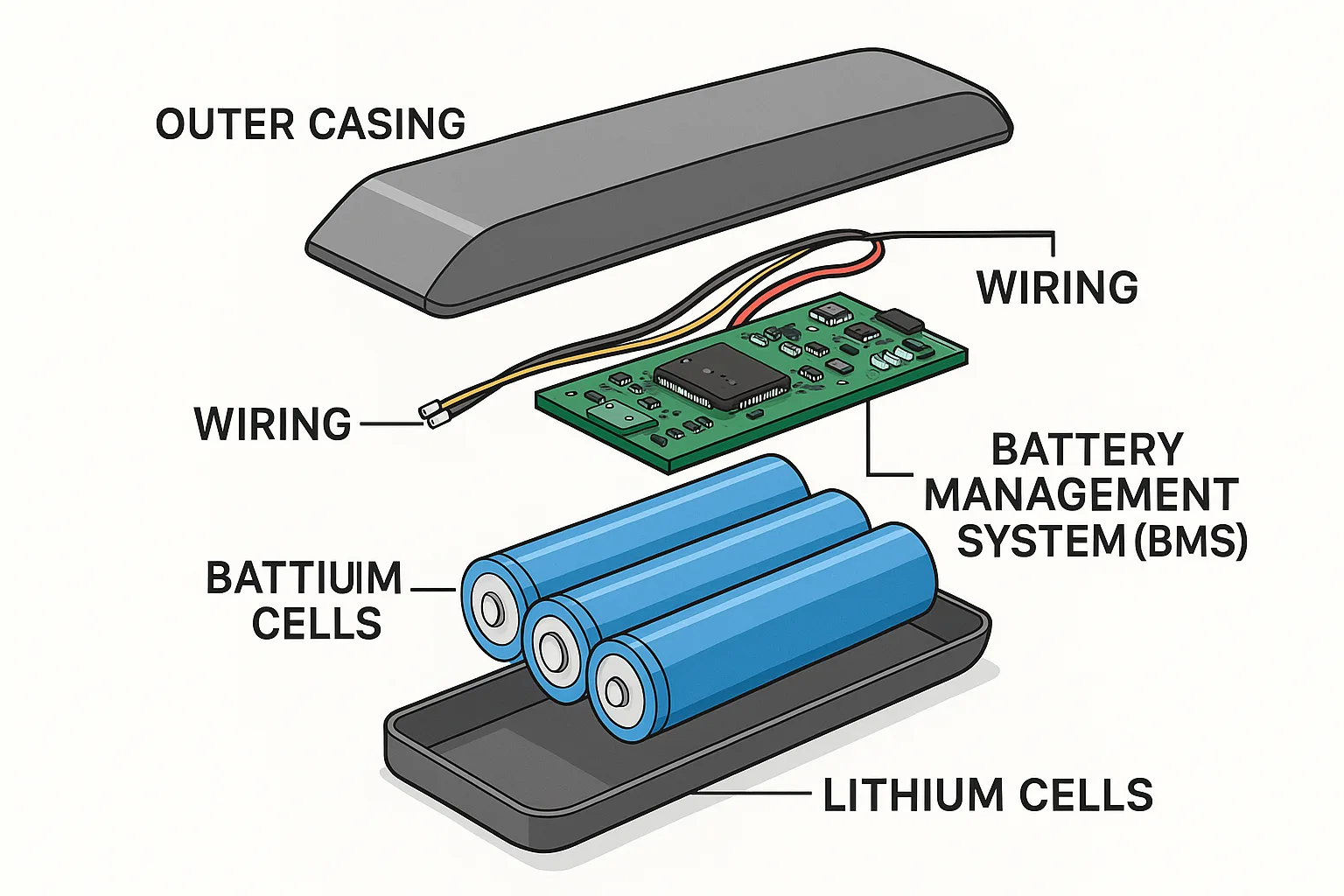

A custom battery pack is specifically designed for your unique application, using carefully chosen battery cells, BMS technology, and casing tailored to exact size and power needs.

Core Components of a Custom Battery Pack

Custom battery packs1 have several important parts. Understanding these components helps you appreciate why they're better than standard options.

1. Battery Cells

Cells are the foundation. We mainly use:

- Samsung, LG, and high-quality Chinese cells

- Each type has strengths in terms of energy density, lifespan, and price.

| Cell Type | Energy Density | Lifespan | Cost |

|---|---|---|---|

| Samsung/LG | High | Long (800-1000 cycles) | Medium-High |

| Chinese Grade A | Medium-High | Moderate (500-800 cycles) | Medium |

2. Battery Management System (BMS)2

This manages charging and discharging:

- Prevents overheating and overcharging.

- Offers smart options with Bluetooth for diagnostics.

3. Customized Casing

This ensures the battery fits perfectly:

- Common types include Hailong, Shark, Dorado, and Rear Rack.

Why Should You Choose a Custom Battery Pack Instead of a Standard One?

You might wonder, why spend more time and resources on custom batteries when standard batteries seem easier to buy?

Companies prefer custom battery packs because they offer exact voltage matching, better safety, easier compliance, custom branding3, and overall improved device performance.

Real Benefits of Custom Batteries

Let's consider some practical advantages:

Perfect Fit and Compatibility

A common pain point is battery-case mismatch. Custom solutions eliminate this headache by fitting your exact dimensions and connectors.

Improved Safety

Custom BMS and precise cell selection significantly reduce the risk of accidents. I've seen products fail due to battery issues—this alone justifies custom solutions.

Easier Certification

Custom batteries are built ready for certifications like UN38.3, CE, RoHS, and UL2271, preventing shipment delays or returns from customs.

| Certification | Importance |

|---|---|

| UN38.3 | Essential for air/sea shipping |

| CE | Mandatory in Europe |

| UL2271 | Important for the US market |

Enhanced Branding and Market Differentiation

Custom packs can have your logo, branding colors, and unique packaging, helping your product stand out.

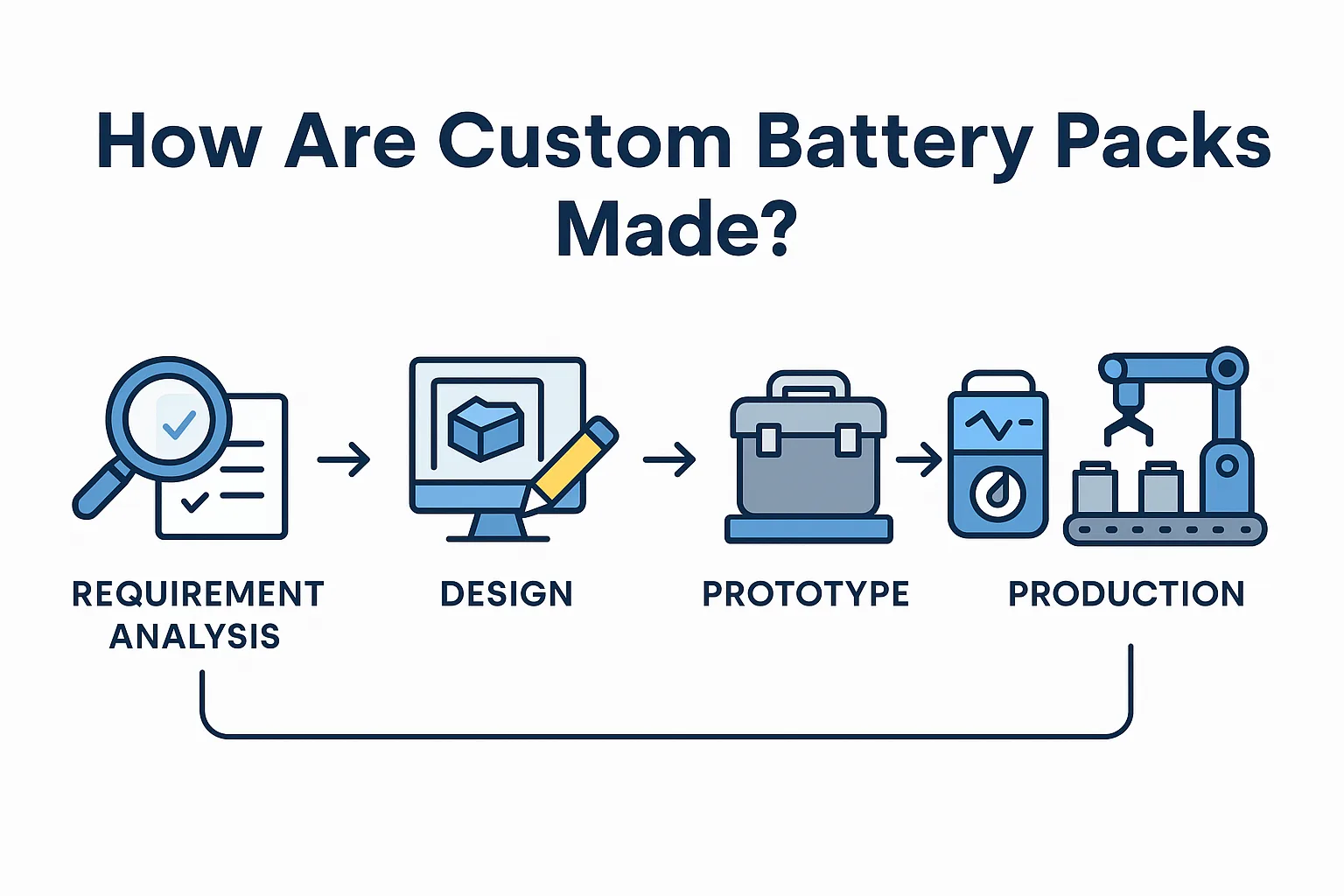

How are Custom Battery Packs Made?

If you're like me, you're probably curious about how your battery is built. Understanding the process makes collaboration smoother.

Custom battery packs are created through careful analysis, tailored design, prototype testing, quality control, and production, ensuring consistent quality and reliability.

Step-by-Step Production Process

1. Analysis of Your Requirements

We start by understanding your exact device specifications:

- Voltage, capacity, and size needs.

- Environmental and regulatory considerations.

2. Engineering and Design

Our engineers design the pack layout, selecting suitable cells and BMS configurations.

3. Prototype and Testing

Before full production, we create samples:

- Conduct thorough testing for safety and performance.

- Adjust designs based on feedback.

4. Mass Production

Production begins with strict quality control:

- Each cell is matched for consistency.

- Every pack undergoes full testing before shipment.

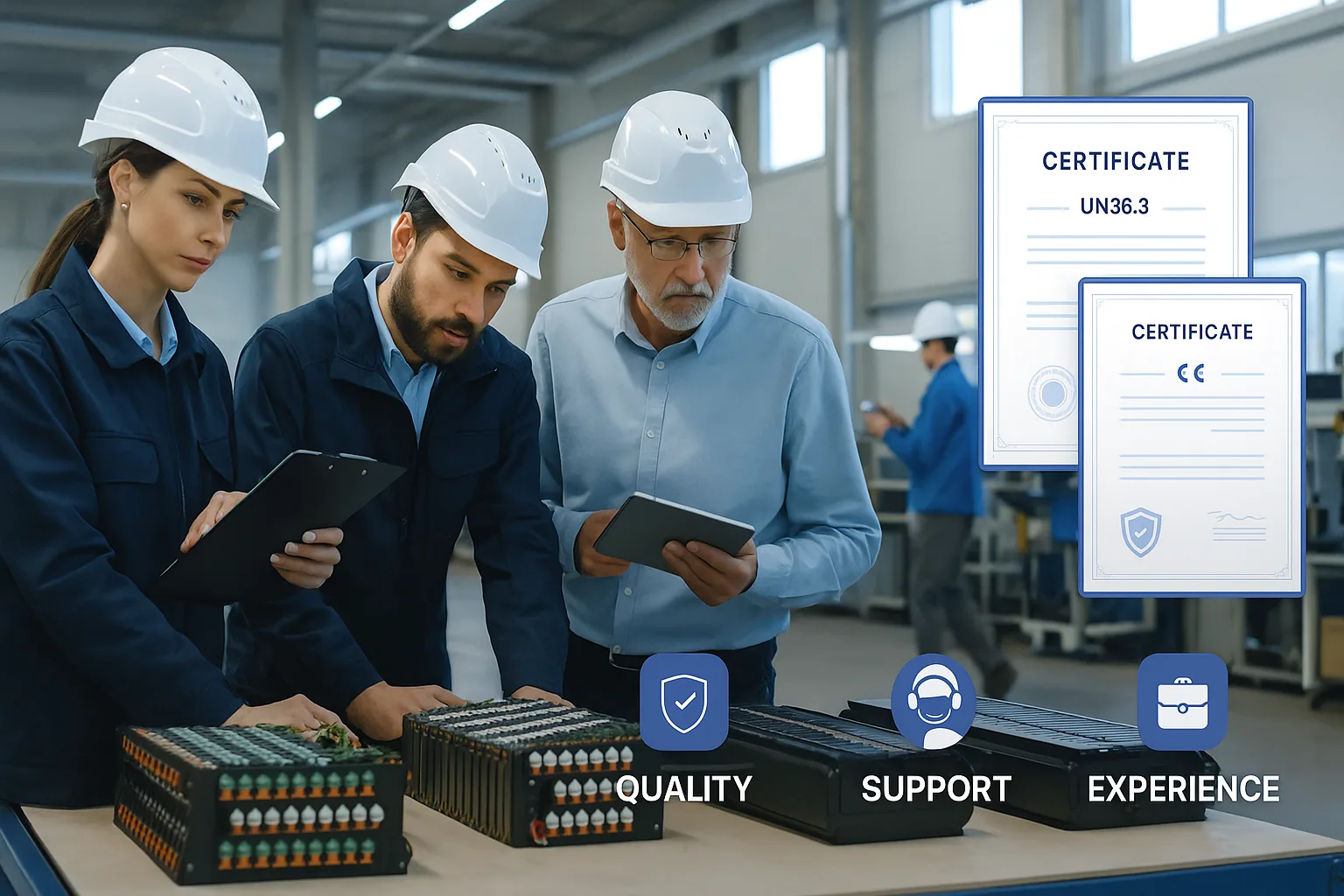

What Should You Look for When Selecting a Custom Battery Manufacturer?

Choosing a supplier isn't easy. I've learned to always consider certain key points to avoid costly mistakes.

Experience, global certifications, BMS design capability, responsive support, and scalable production capacity are critical when selecting a custom battery pack manufacturer.

Essential Criteria for Choosing a Supplier

Proven Industry Experience

Experience means fewer errors. Check your supplier’s history and projects they've successfully completed.

Certifications and Compliance

Always verify your supplier can provide necessary documentation, especially:

- UN38.3, CE, MSDS, RoHS, and UL2271.

BMS Expertise

Ensure your supplier understands BMS technology deeply. Smart BMS solutions with diagnostics capabilities are a bonus.

Support and Communication

Choose suppliers who respond quickly. Trust me, it saves headaches later.

Flexible and Scalable Production

Confirm your supplier can meet your current needs and scale production quickly if needed.

| Key Factor | Why It Matters |

|---|---|

| Experience | Reduces mistakes and risks |

| Certifications | Prevents shipment/custom issues |

| Support | Solves issues promptly |

| Scalability | Meets growing business demands |

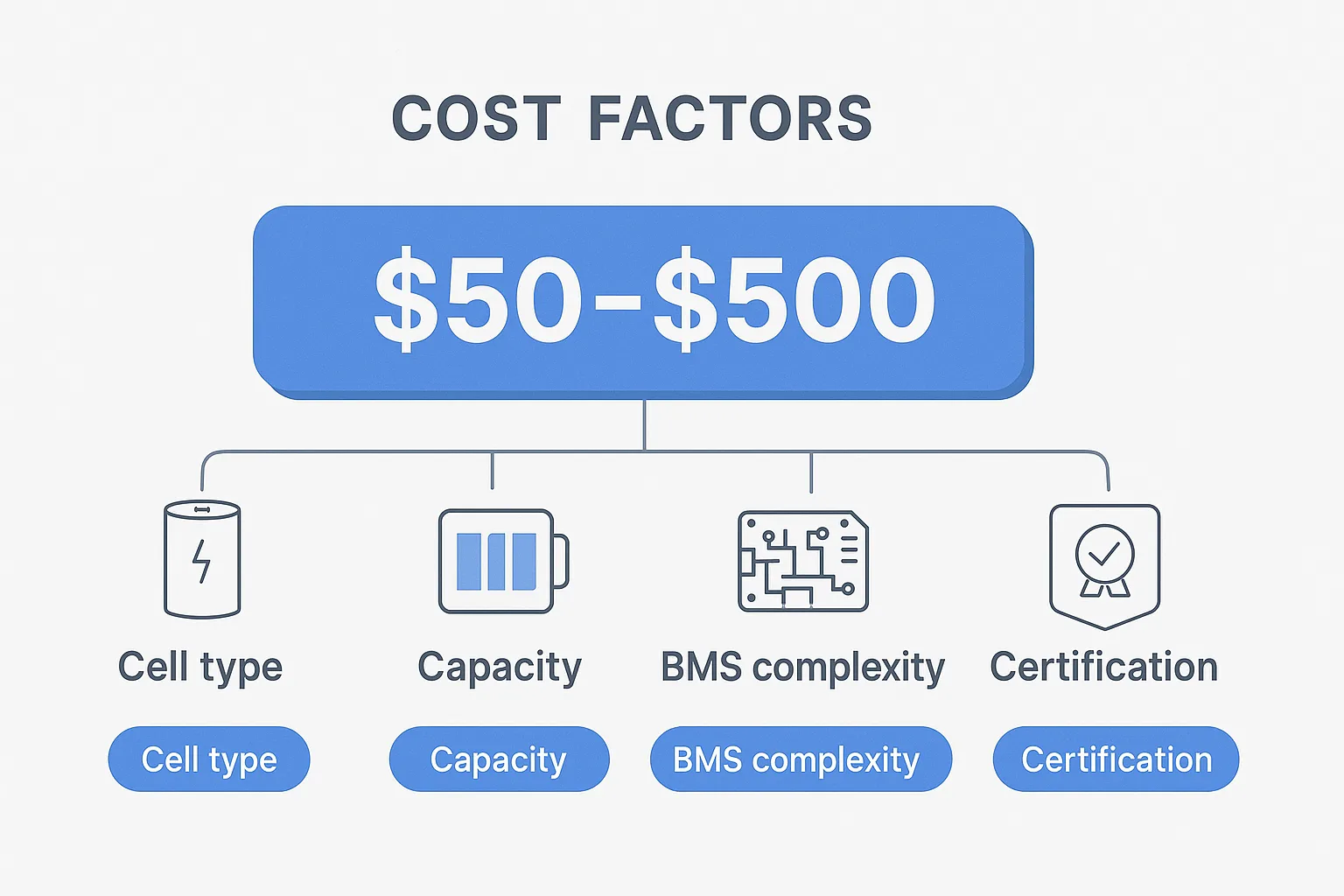

How Much Do Custom Battery Packs Usually Cost?

Budgeting for custom packs can seem tricky at first. Costs vary widely, but transparency helps you plan better.

The price for custom battery packs depends on chemistry, capacity, complexity, and certification, generally ranging from $50 to $500.

Understanding Cost Factors Clearly

Here's what drives your battery pack cost:

| Factor | Impact on Cost |

|---|---|

| Cell Quality (Samsung/LG vs Chinese cells) | Significant |

| Battery Capacity (Ah) | Moderate |

| BMS Complexity (basic vs smart Bluetooth) | High |

| Custom Packaging and Branding | Moderate |

| Certification Requirements | Moderate to High |

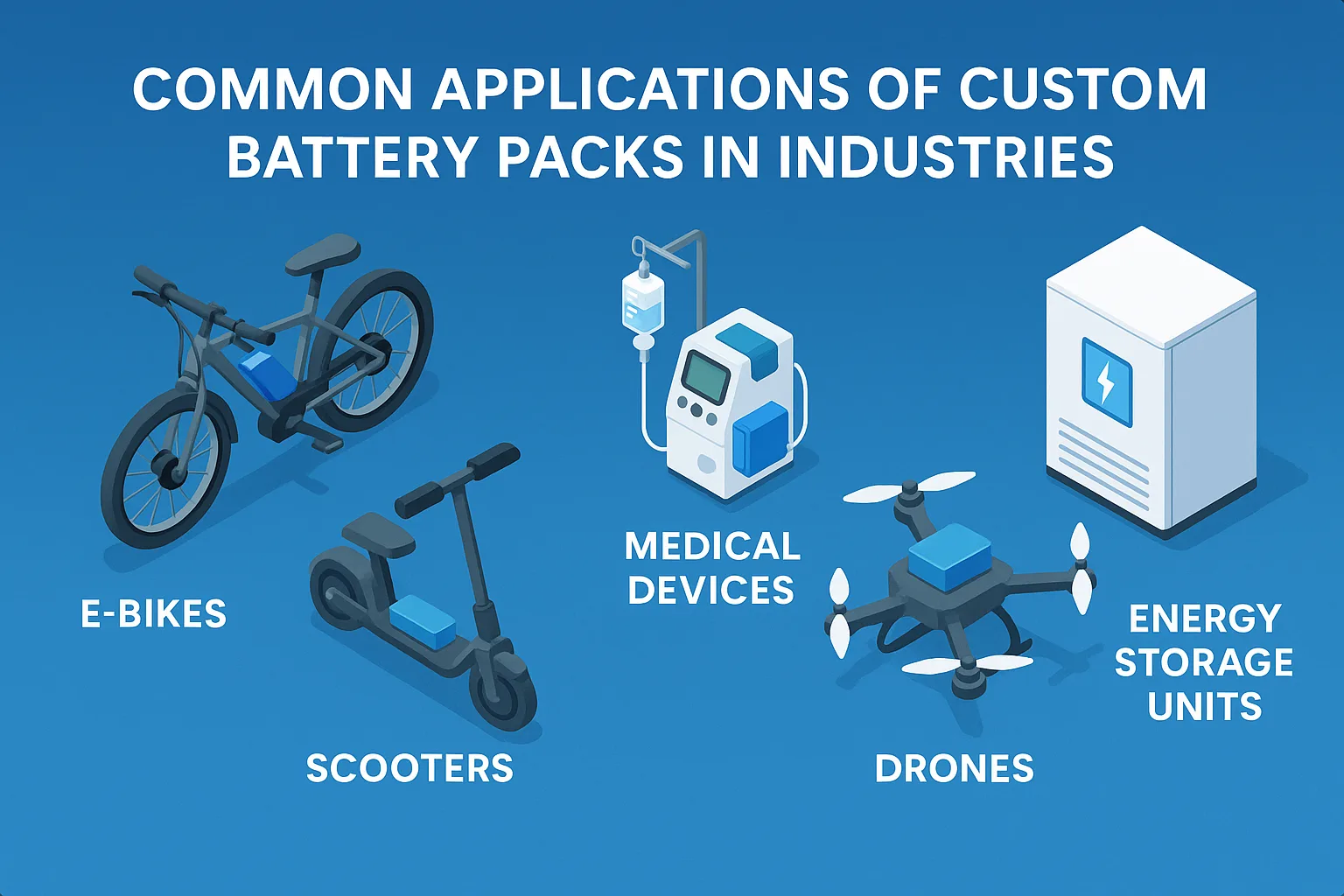

Common Applications of Custom Battery Packs in Industries

In my experience, the flexibility of custom batteries makes them useful across diverse industries.

Custom battery packs are widely used in electric vehicles, medical devices, robotics, renewable energy systems, and specialized electronics.

Popular Use Cases

Here are common examples where custom batteries excel:

- E-Bikes and Scooters: Precise power requirements and safety demands.

- Medical Equipment: Reliability and certification compliance.

- Robotics: Size and weight constraints.

- Renewable Energy Storage: High durability and cycle life.

- Specialized Electronics: Unique voltage and size requirements.

Conclusion

Custom battery packs provide unmatched compatibility, reliability, safety, and branding opportunities, significantly boosting your product’s market performance and customer satisfaction.

-

Explore the advantages of custom battery packs to understand how they can enhance your products and business performance. ↩

-

Learn about the critical role of BMS in ensuring safety and efficiency in battery packs, which is essential for any tech product. ↩

-

Discover how custom branding can differentiate your products in the market and enhance customer recognition and loyalty. ↩